Industrial Wastewater Solutions

Industrial process water, rinsing water, washing and other industrial processes produce large amounts of wastewater containing a variety of highly concentrated pollutants. All this wastewater needs to be treated in internal systems before it can be discharged into public sewage systems or rivers, lakes, oceans. And many times, we cannot clearly give the nature of wastewater, such as the composition of wastewater, the composition of TDS, and many times, the components in wastewater are not economically valuable, recycling is not economical, or you need to highly concentrate wastewater, then using thermal separation technology to treat wastewater is undoubtedly the best choice. When designing evaporation and crystallization equipment, we need to consider many factors, such as the composition of raw materials, the purpose of concentrated products, energy conditions, local conditions, the price of electricity or steam, the site, the layout plan of the enterprise, and so on.

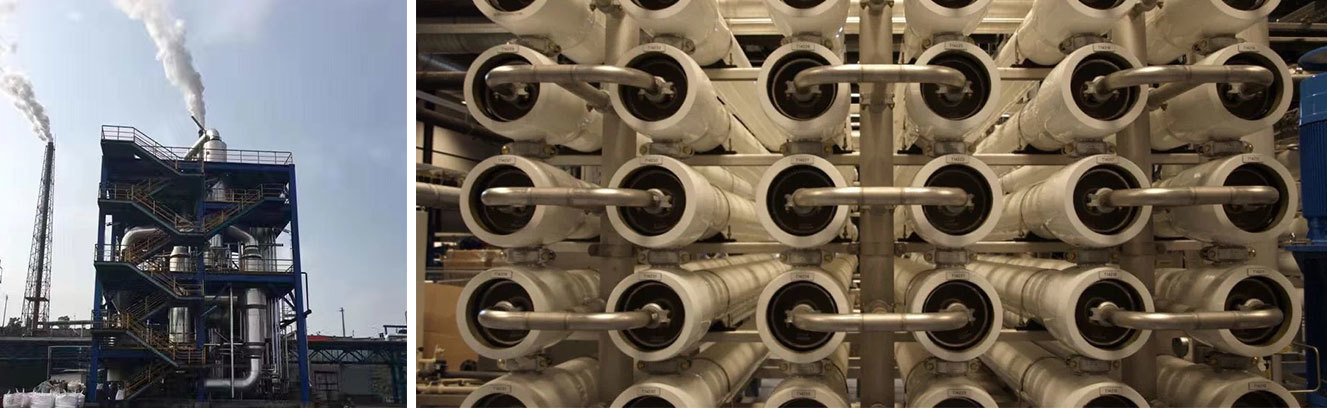

The operating cost of evaporative crystallization equipment is mainly in energy consumption. The new generation of MVR evaporator is currently internationally recognized energy-saving and environmentally friendly evaporation concentration equipment, it does not need to use steam, its basic principle is to steam from the separator after the secondary steam is compressed by the compressor, supplementing one-tenth of the energy, the steam temperature rises, the enthalpy increases, and then enters the evaporator heating chamber to provide heat to the circulating material, and the steam itself condenses and releases latent heat, and the condensed hot water can be exchanged with raw materials. Cycle reciprocating, steam is heated by the compressor, the material is heated by steam evaporation, steam can be fully condensed into water, hot water and then feed preheating, so interlocked, every heat has been fully utilized, raw materials in, out of one is crystalline solid, one is room temperature cooling water, environmental protection and energy saving.

This is the industrial waste liquid zero discharge solution suitable for electroplating industry, coating production industry, pharmaceutical and pesticide industry, metal processing industry, paper industry and crude oil production industry, etc., through the comprehensive use of membrane technology, biochemistry, oxidation, MVR evaporator and other technologies, the useful substances in the wastewater are recycled, and the distillate water can be directly reused or discharged up to standard, which greatly reduces the treatment cost of waste liquid.