Deodorization system

(1) Chemical deodorization method

The purpose of deodorization is achieved by using irreversible chemical reactions between odor components and the main components of chemical liquid to generate new odorless substances. This method requires the configuration of corresponding chemical agents for different odorous gases to improve the utilization rate of the agents, and the liquid is brought into contact with the odorous gas through a scrubbing tower to react and remove the odorous substances. This method is highly specific to odorous components, and the cost of chemical agents is relatively high.

(2) Ion deodorization method

It includes an ion generator and a purification system. The ion generator decomposes oxygen molecules in the air into positive and negative oxygen ions with positive or negative charges. By using its strong activity, the chemical chain of odorous gas molecules is opened in contact with odorous gas molecules to generate water and oxides. With the help of a ventilation pipe system, a controllable concentration of positive and negative oxygen ion air is sent into the space where odorous gases and odors are emitted, and reacts with gas pollutant molecules in a very short time, effectively curbing the diffusion of gas pollutants and reducing the concentration of indoor gas pollutants.

(3) Biological method

A. Biofilter The biofilter deodorization method mainly includes three parts: the contaminated site sealing system, the odor collection and transportation system, and the biological deodorization filter.

This process adopts a common filter structure. The deodorization of odor is achieved in the biofilter. The filter material serves as a carrier for the survival of microorganisms, and the microorganisms devour the odor components in the air.

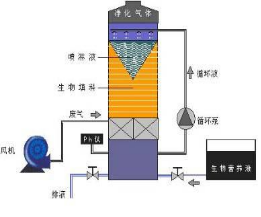

Schematic diagram of biological deodorization system

The odor enters the humidification area through the inlet for humidification, and the absorption, dust removal and humidification pretreatment of the odor water are completed in this area. The unremoved odorous gas enters the filtration area of the biological filter bed again. When passing through the filter material filtration layer with biofilm growing on the surface, the pollutants are transferred from the gas phase to the surface of the biofilm, and the odorous components entering the biofilm are removed under the oxidation and decomposition of microorganisms. Microorganisms use the absorbed odorous components as an energy source for further reproduction. Thus, the purpose of deodorization is achieved.

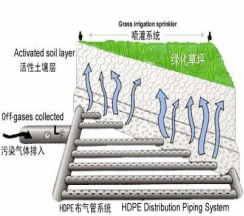

B. Soil filter The biological soil deodorization equipment uses the microorganisms cultivated and domesticated in the biological soil to oxidize and decompose the components of the odor when it passes through the biological soil. When the odor contacts the breathable active soil layer containing a large number of microorganisms, it will be completely oxidized by the microorganisms and converted into CO2 (carbon dioxide) and water and microbial cell biomass, thereby achieving the purpose of deodorization. The specific treatment process is shown as follows:

(4) Full-process deodorization process

The deodorization system consists of a microbial culture system and a deodorizing sludge dosing system. The microbial culture system mainly refers to the installation of a certain number of microbial culture boxes in the biological pool of the sewage treatment plant. With the help of the biological pool structure and a certain amount of air, the deodorizing microorganisms can be proliferated in the biological system and form a certain number scale.

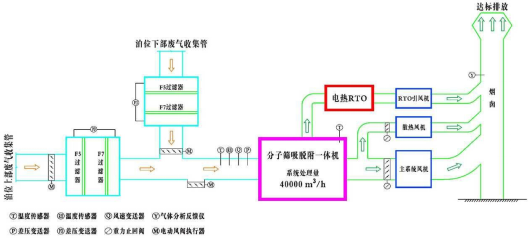

(5) Adsorption pyrolysis method

The system uses molecular sieve arrays to concentrate the adsorption of odor. When the adsorption reaches a certain amount, it is desorbed. After desorption, it is subjected to high-temperature electric pyrolysis to remove harmful substances in the odor. Its emissions are far lower than the national standard. The system takes into account the changes in national and local industry regulations, and the treatment process remains forward-looking and advanced, and has the potential for upgrading in the future; it occupies a small area, is easy to maintain, has low operating costs, and the construction cost + long-term operating costs must be low; there are no safety hazards, no secondary pollution, and it is suitable for the industrial sewage of this project; but due to the late advent of the system, there are not many actual cases.

Typical flow chart of adsorption pyrolysis deodorization process

The above five methods are commonly used deodorization methods in domestic sewage treatment plants. The ion deodorization method has the advantages of simple equipment, good deodorization effect, small footprint, flexible operation, convenient on-site installation and management, etc. It is particularly suitable for the treatment of separate and dispersed odor sources, and the cost is relatively low. The biological filter method has a good deodorization effect and is mostly used to collect odors from various odor sources for centralized treatment. It is suitable for occasions with large amounts of odor to reduce economic costs. The chemical deodorization method has a high cost of chemical agents and is not commonly used. There are currently few engineering examples of the adsorption pyrolysis method and the whole process deodorization process.