TECHNOLOGY

Membrane core process

TIME:

2023-04-17 11:24

In order to solve the shortage of water resources or the total amount of local sewage discharge control, the sewage treatment plant in the industrial park has been upgraded and renovated.

The water reuse process of the double-membrane method is adopted

◆A/O method + membrane bioreactor (MBR) MBR membrane + nanofiltration (NF)/reverse osmosis (RO or STRO) process

◆Ultrafiltration (UF) / immersion ultrafiltration (MF) + nanofiltration (NF) / reverse osmosis (RO or STRO or DTRO) processes

Advantages of the double-membrane process

◆It can be directly connected with the discharge sewage, and the upper system is convenient and modular;

◆It can effectively remove impurities such as organic matter and salt, and the quality of the produced water is stable and better than the quality of industrial tap water;

◆Small foot space, high degree of automation, easy to manage.

|

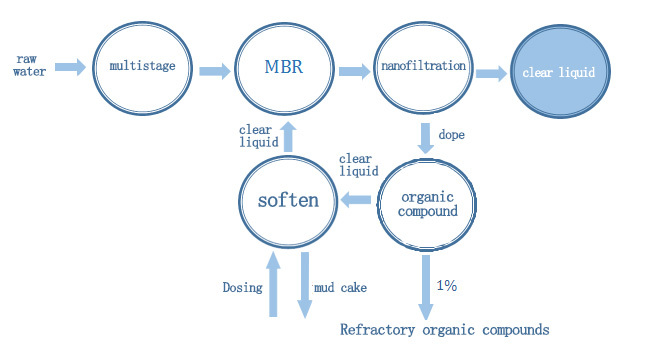

Near-zero emission process/equipment Enhanced denitrification multistage biological pool + ultrafiltration (UF) + nanofiltration (NF) + organic separation membrane The landfill leachate adopts a multi-stage influent multi-stage biological pool treatment process, which has the effect of strengthening nitrogen removal, greatly improving the efficiency of biochemical treatment, and its effluent can be discharged up to standard after MBR and nanofiltration. The refractory organic matter in the nanofiltration concentrate is separated and extracted by the organic separation membrane and returned to the incineration plant for treatment, and no concentrated liquid is generated in the whole system. |

|

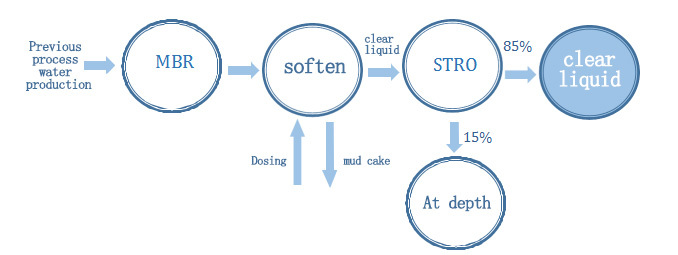

Membrane Bioreactor (MBR) + Softening (TUF) + Tube-managed Reverse Osmosis (STRO) This process is mainly used in incineration plants, MBR water after TUF treatment, effectively remove calcium hardness and magnesium hardness in the sewage, alleviate the membrane fouling cycle, extend the service life of the membrane, and increase the membrane water yield to 85%. After TUF treatment, the concentrate produced by the STRO system can better avoid fouling problems during evaporation. The entire system is virtually emission-free. |

|

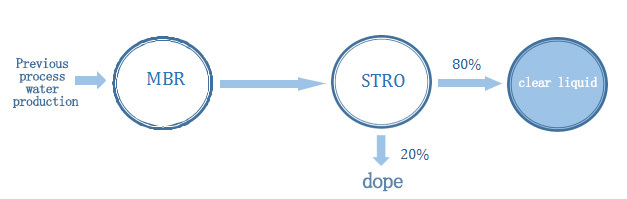

Membrane Bioreactor (MBR) + Tube-Operated Reverse Osmosis (STRO) MBR water is directly processed by STRO system after production, and the whole system has the characteristics of simple process, stable water production and convenient operation, and the water yield rate can reach more than 80%. |